Wille 475Δ

The first machine in the fourth-generation Delta range.

Wille 475 is the best-selling machine for environmental services in its category, with the driver always in focus. Despite its compact size, the Wille 475 features properties typical of much larger machines, and in it not even long working days feel tiring. The cab is all new and clearly larger than before. The driver has an excellent view in all directions from his seat. The most significant technical innovation is the loader valve with electric control. It enables the driver to adjust the loader’s operating speed precisely as desired, and to save individual settings for different work attachments. The new, exact cruise control makes it possible to master varying tasks easily and safely. Four different driving modes. These modes help the driver find ideal driving style for each individual task.

The Wille 475 has a modern look that can be easily modified to underpin the customer’s own brand simply by replacing the paintable plastic parts.

A lookout office with changing landscapes

Thanks to the curved front and rear windows, the glass door and the instrument panel with low construction height, the view from the panoramic cabin is more open than before. The glass door has a sliding window and there are extra LED rear lights in the upper corners of the cab. The noise level in the cab is lower than before and the controls are positioned in an ergonomically correct way.

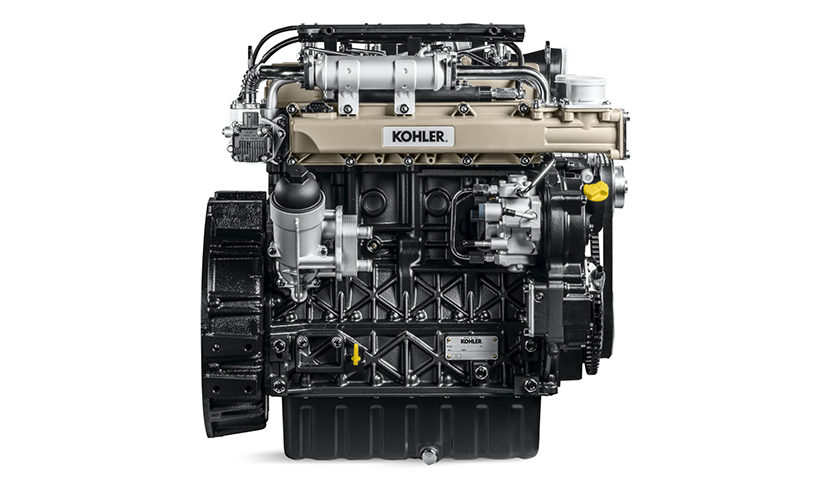

Insignificant emissions

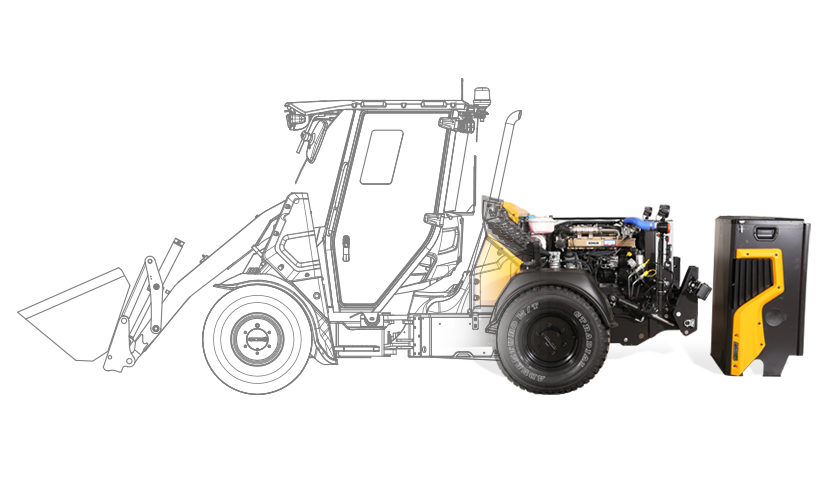

The engine of Wille 475 is a Kohler diesel of 55 kW is equipped with a particulate filter and a catalytic converter and meets the emission requirements according to Stage V. Like all the other Wille models, also Wille 475 can use the second-generation 100% HVO biodiesel as fuel.

Everything under control

The driver can now enjoy a new large display that provides comprehensive information about the machine’s functions. The user interface has also been completely redesigned. All the functions on the display are controlled by a navigation roller integrated in the armrest. There are shortcut keys next to the navigation roller for the most frequently used functions. This setup serves the user perfectly. The most important and most often used functions have been concentrated within easy reach of the driver’s right hand to make the working easier and more efficient.

Access to service points

The engine bonnet of the Wille machines opens completely thus making checking of fluid levels in the engine compartment and servicing of the machine easier. If necessary, the bonnet can be slid open and removed by lifting. After the service, the bonnet can be closed simply by sliding it back. Easy access to the engine compartment reduces the time required for maintenance and inspection allowing this time to be used for productive work instead. The fuses and circuit boards that are located on the right-hand side of the cab can be easily accessed from outside via an opening door. A clear fuse map on the inside of the door shows where the fuses are located.

Get the job done at once

In Wille the work attachments can be connected to the front, to the rear and on top of the bonnet. All the equipment required for multiple work stages can be attached at once: you can sprinkle the road while brushing, and transport up to ten times more water on top of the bonnet than what the washer’s own water tank can hold. Plough snow, spread sand and fill the sand spreader from the platform on one tour. This will save you both time and fuel as you don’t have to return to where you started from to change equipment or fill the tanks before the job is finished.

Intelligently economical

The Wille 475 comes as standard with the Automatic Eco Drive feature that reduces consumption of fuel and noise. It adjusts the engine speed to the range of best efficiency, if high engine revolutions are not needed. The consumption of fuel and emissions are then significantly lower. The biggest gains are achieved during transfers.

Advanced controllability

Smart Drive provides a more ergonomic alternative to the inch pedal. When the Smart Drive mode is selected, the accelerator pedal will programmatically change to drive pedal. To set the desired engine speed, simply adjust the hand throttle and control the driving speed by using the accelerator pedal. Smart Drive is a way for a true Wille professional to make the working easier and more efficient.

Soft Drive is an option for precision work

You can make the behaviour of Wille 475 smoother during driving by selecting Soft Drive as the driving mode. The machine’s accelerator pedal will then respond more slowly. The Soft Drive mode is ideal, for example, for working with forklift forks. It not only improves the precision of the work but also ensures the safety of the driver and the surroundings.

Correct movements for each work attachment

The driver can at will create a work-attachment-specific profile for himself or any work attachment. Such as, for example, sweeper, bucket and washer. An individual work-attachment-specific maximum speed (0 – 100%) can be assigned to the loader movements, the cylinder hydraulics and the maximum speed of the engine. When changing job or work attachment, the optimised values for the work attachment can be easily retrieved via the Wille user interface. This makes working efficient and safe.

Ease at work and during transfers

A new feature of Wille 475 is the precise cruise control. It works with the logic familiar from cars, making, for example, ploughing of snow and sweeping of pedestrian lanes easier. The driver can now focus on the task at hand without having to concentrate on speed adjustment. The driver can also better keep an eye on the surrounding area to avoid dangerous situations. Cruise control also brings additional comfort for transfers.

Controlled use of grease

With the optional new Smart Lube system, the user can control the amount of grease applied by the central lubrication system. The amount of grease is adapted to the current work – neither too much, nor too little. The amount of grease can be adjusted on Wille’s display as follows. Off , Low , Medium, High . In addition, the system can be operated manually. If the machine is stationary or travelling faster than 35 km/h, the system will not apply grease. This way, the system helps avoid excessive lubrication, at the same time reducing consumption of grease and the need to add grease into the reservoir.

Pictures